China Manufacturer for Plastic Barb Fittings - Hydrauic Brake Tube Assembly Yb/T4164-2007 – Jinxing

China Manufacturer for Plastic Barb Fittings - Hydrauic Brake Tube Assembly Yb/T4164-2007 – Jinxing Detail:

The double layer welded pipe has good leakage resistance, high blasting performance,excellent

reprocessing,outstanding anti-fatigue performance,high internal cleanliness,accurate geometry and so on.performance paramete: tensile strength Rm≥ 290Mpa Yield strength: Rel≥180Mpa Percentage elongation after fracture: A ≥ 25% The cleanliness of inwall: Residue≤ 0.16g/㎡.

Free length

The length of the exposed part of the hose between the two pipe joints on the hose assembly in a straight state.

Brake hose connector

In addition to the clamp, a connecting piece attached to the end of the brake hose.

Permanently connected pipe joints

The connected pipe joints shall be assembled by crushing or cold extrusion deformation, or the pipe joints of damaged bushings and ferrules shall be replaced every time the hose is reassembled.

burst

A fault that causes the brake hose to be separated from the pipe joint or leaks.

Vacuum piping connector

Refers to a flexible vacuum transmission conduit:

a) It is a connector between metal pipes in the brake system;

b) No pipe joints are required during installation;

c) When assembling, its unsupported length is less than the total length of the part that contains the metal pipe.

Test conditions

1) The hose assembly used for the test should be new and should be aged for at least 24 hours. Keep the hose assembly at a temperature of 15-32°C for at least 4 hours before the test;

2) For the hose assembly for flexural fatigue test and low temperature resistance test, all accessories, such as steel wire sheath, rubber sheath, etc. must be removed before being installed on the test equipment.

3) Except for high temperature resistance test, low temperature resistance test, ozone test, and hose joint corrosion resistance test, other tests must be carried out at a room temperature of 15-32 °C.

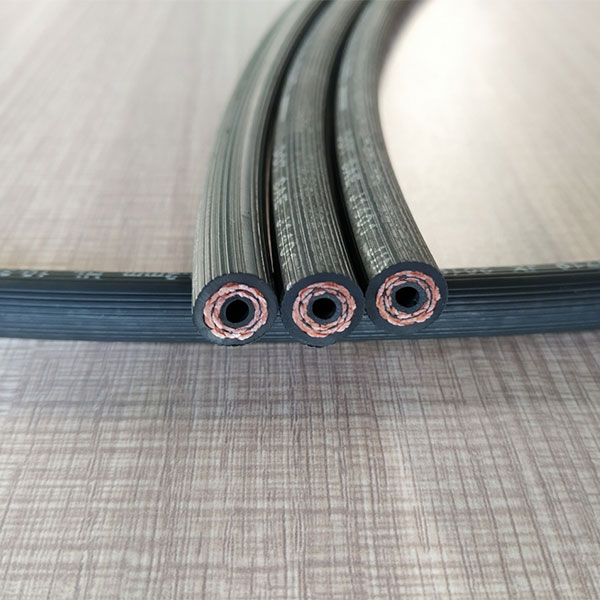

The hydraulic brake hose assembly is composed of a brake hose and a brake hose joint. There is a permanent connection between the brake hose and the brake hose joint, and the connection is realized by crumpling or cold extrusion of the joint part relative to the hose.

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for China Manufacturer for Plastic Barb Fittings - Hydrauic Brake Tube Assembly Yb/T4164-2007 – Jinxing , The product will supply to all over the world, such as: Czech republic, America, Latvia, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products !

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.